5 Insulation Zones for a Pole Building

Proper pole building insulation zones play a crucial role in creating a comfortable and energy-efficient space. Insulating these 5 essential areas can significantly reduce heating and cooling costs while improving your workspace or storage environment.

Nobody enjoys working on their tractor in a pouring downfall or changing their oil in a snowstorm. If given the choice, most people prefer the comfort and convenience of a sheltered workspace. For many though, heated shops are a luxury they can’t afford. Or perhaps the garage and the barn is packed full, and they just don’t have enough space.

It might be time to build.

The most cost-effective option is the post-frame building. In the past, pole barns were reserved for agricultural housing, or for lean-to sheds tucked away in the back corner of the property. Modern post frame buildings are so much more. A pole building could be a fully finished garage, an insulated workshop, climate-controlled storage, or an event venue. Size, shape, and color of a pole barn are only limited by imagination. Many homeowners are finding their dreams of extra storage, or a better workspace can become reality.

Why Insulate?

Although insulating isn’t a requirement depending on your application, it needs to be taken into account if the inside environment is of any concern to the owner. Energy efficiency is a vital factor in any construction project. Proper insulation is a must to keep heating and cooling costs low and maintain comfort. The outside temperature will transfer to the inside and create an inhospitable environment without this defense.

Let’s dive into some ways to properly insulate your pole building.

But first, what is R-Value?

Understanding R-Value:

The R-Value is a measure of thermal resistance indicating the efficiency of insulation materials. In other words, it measures how well insulation resists the flow of heat. Higher R-Values signify greater insulating power, contributing to energy savings and enhanced comfort.

5 Key Areas to Insulate in Your Pole Building

1. Upgrade Doors and Windows for Better Thermal Performance

Believe it or not, the doors and windows you choose affect your energy efficiency. Drafty doors and low-grade windows allow inside air to escape and outside air to seep through to the inside.

Choose a good weatherstripping and insulated garage doors with a minimum R-Value of R-13.5 to enhance heat retention and minimize condensation, ensuring a comfortable and dry interior environment.

Pick windows with high UV protection, good condensation resistance, and minimum air leakage to extend your energy efficiency.

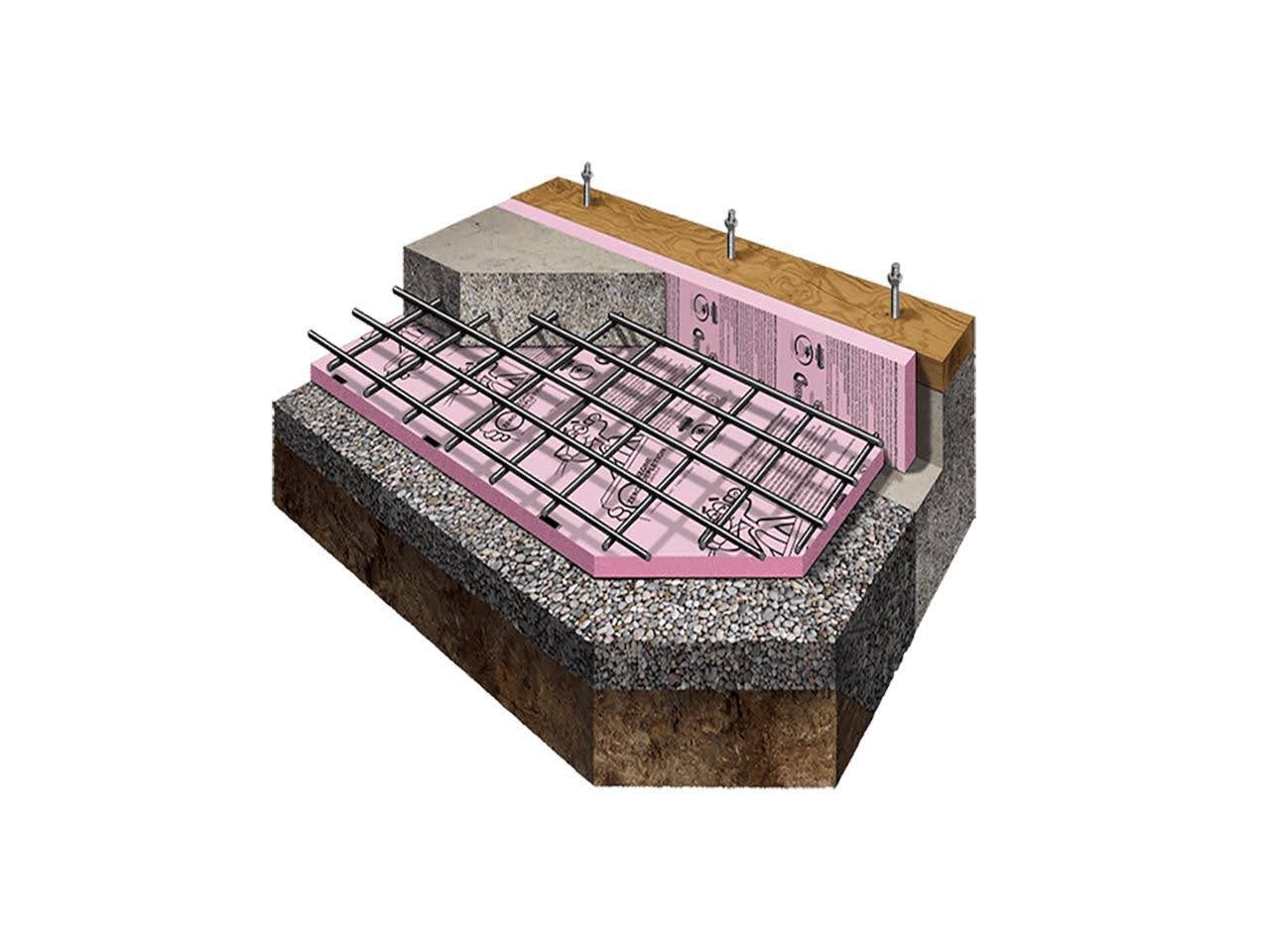

2. Insulating the Foundation: Keep Ground Chill Out

A concrete slab foundation is a must for interior finishing. To minimize heat loss through the ground, consider integrating slab edge insulation into your design. This is generally a 2” foam-board barrier around the perimeter of your slab.

Bonus Tip:

Install radiant heat tubes on the ground before pouring the concrete foundation to minimize heat loss through the ground and create a more comfortable space.

3. Choosing the Right Wall Insulation System

One of the most important lines of defense in a pole building are the walls. The simplest reason is that the wall panels generally have the most surface area in the building. Insulation helps combat the flow of heat, greatly reducing heat loss.

Here are 4 different types of wall insulation:

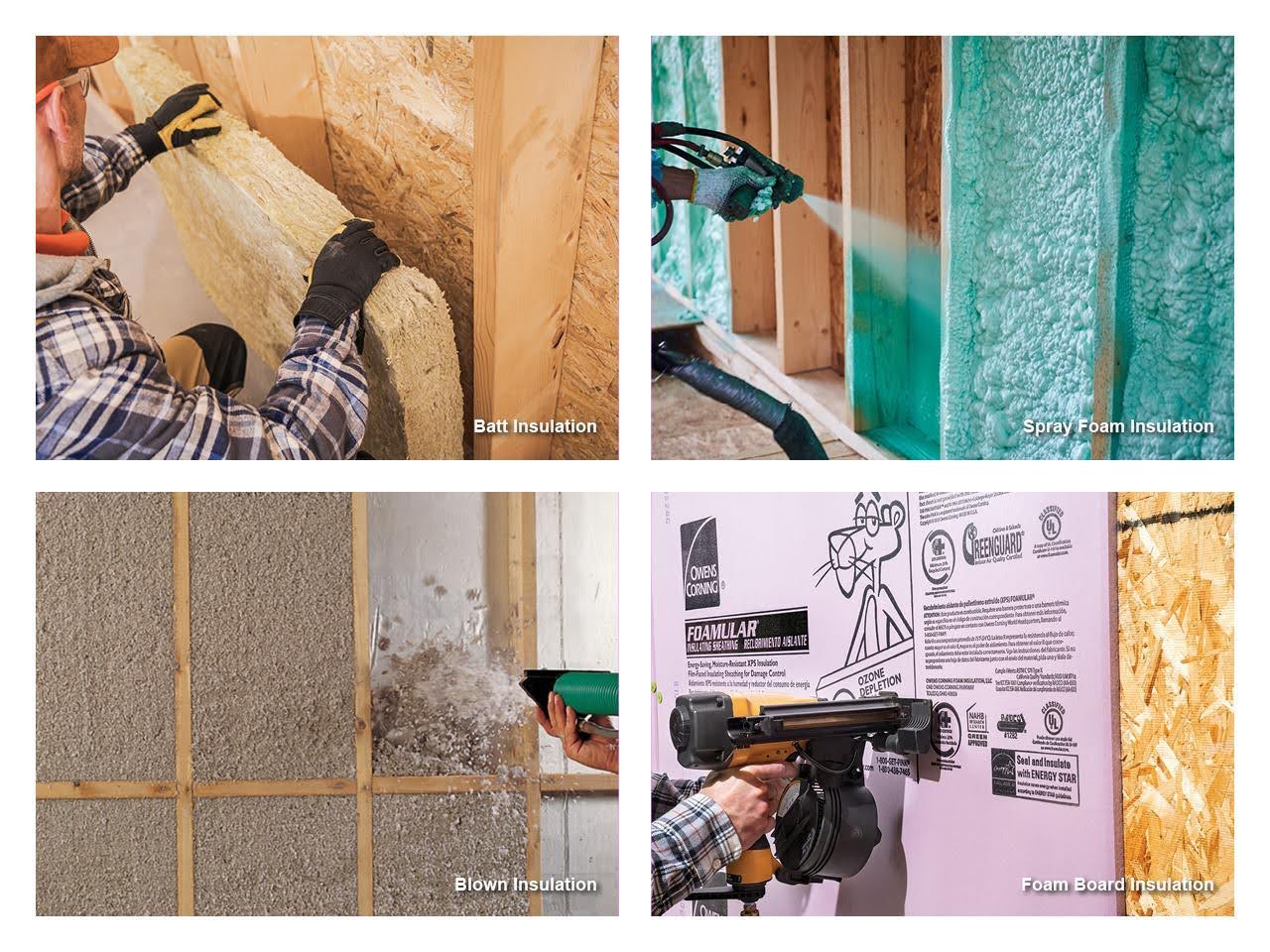

- Batt Insulation

This is the most cost-effective and the preferred insulation solution for most installers. It does an excellent job helping to regulate temperature. One bonus for using fiberglass or mineral wool batts in a pole barn is because of the stud spacing—8’ instead of the traditional 16”. This allows long spans of insulation between the posts, meaning less gaps for heat to escape, and faster installation.

Aim for an R-Value of R-21 or higher to ensure optimal thermal efficiency.

- Spray Foam Insulation

This is a more expensive option, but a popular one among professional contractors. Because it expands as it dries, it fills every crack. It’s also a very dense material, making it a strong defense against air flow and moisture.

To use spray foam effectively, most experts recommend a vapor layer between the sticky insulation and the outside steel panels. This will not only add an extra layer of defense against moisture, but if wall panels need replaced in the future, it can easily be done without disturbing the spray foam.

- Blown Insulation

Having a similar effectiveness as batt insulation, blown insulation is another viable option. However, the method of application is entirely different. Blown insulation is typically fiberglass, mineral wool, or cellulose, made from recycled paper products. This type of insulation is commonly used in attics, but a variation is used for walls. Blown insulation for walls is chemical infused so it sticks to itself and the wall. Plastic sheeting is then installed to keep the insulation in place behind the interior walls.

- Foam Board Insulation

The rigid foam board is a great option for insulating walls. Dupont’s Styrofoam XPS Insulation Board is the industry standard. Its solid-slab design makes it easy to cut to fit between studs and is easy to install. It also won’t sag or break down over time like loose insulation or batts. It comes in various styles, including tongue and groove, allowing for a tight fit and a sealant for air, moisture, and pests.

4. Attic Insulation to Retain Rising Heat

The next location to insulate in a pole building is the attic. Some post-frame structures don’t have attics, so this isn’t for every building. However, if the pole building has a ceiling, this is an important addition to your insulation framework. Heat rises, so adding an insulation barrier above the ceiling will keep more warm air circulating in your building and keep it from escaping out the top.

The most common applications are fiberglass batts and blown insulation. Blown cellulose is often the most economical option. There’s no need to cut or shape insulation for a perfect fit. The loose fill conforms to every nook and cranny and creates a thick blanket of insulation. It is also easy to install with a commercial insulation blower. Target an R-Value of R-38 or above for superior insulation performance.

5. Ceiling Barriers to Maximize Indoor Temperature Control

The final spot for your insulation barrier is right at the top. Ceiling insulation is especially important for buildings without an attic. It keeps hot air in and cold air out. When combined with attic insulation, the ceiling barrier will help regulate the attic temperature, benefiting the rest of the building.

A vapor barrier like double-bubble between the roof panels and the trusses is a great option, but it’s not the only one. You can use batt insulation, spray foam, or both. Foam board is also a great option and doesn’t require a ceiling beneath it. It’s all a matter of preference and which one makes the most sense for each project.

Final Thoughts: How to Choose the Best Insulation for Your Pole Barn

Whichever insulation method you choose will greatly increase your energy efficiency and lower your energy bills. It can be a high cost up front, but the rewards are worth it.

Which insulation will you choose? Let us help you decide.

Keep in mind that if the pole building in question has already been built, it’s not too late. Most of the insulation applications in this article can be installed after construction. If you are looking to improve the interior environment and maximize energy efficiency, it’s time to insulate.

For a personalized consultation to explore the ideal interior package that meets your specific needs, feel free to reach out to us.

Timberline Buildings has been constructing high quality pole barns in Pennsylvania since 2003. With attention to detail and a focus on excellent service, pole buildings from Timberline Buildings are built to exceed your expectations. Ready to get started on your new pole barn? Contact us today for your free 1-day quote.