Can you Direct Bury Wooden Posts?

When planning pole building construction, understanding can you direct bury wooden posts is essential. Wooden posts are the foundation of these structures, but choosing the right method and materials greatly impacts durability. Before digging post holes and setting posts, consider options that extend your building’s lifespan and improve structural integrity—saving you from costly repairs down the line.

Let’s take a look at the options.

Raising the Sheridan Barn, 1872, Shorpy.com

The Traditional Approach to Direct Burial of Wooden Posts

Post-frame structures have been around for 100 years. They’re built upon the principle of simple but sturdy construction to cut costs and not space. Think of the arch of a bridge. Dozens of posts work together to hold up a long platform. Its strength is in its numbers, the materials used, and how they fit together. In a pole building, builders set wooden posts in the ground, spacing them farther apart than typical studs, allowing for large open spaces without the need for interior walls.

Bridges are built with steel for maximum strength, but post-frame buildings use wood to keep costs low. Since bare wood can rot when in direct contact with the ground, treated lumber became the industry standard.

Chemically infused lumber, or pressure-treated wood makes the wood itself resistant to decay and insects. This is a powerful improvement, taking the lifespan of the wooden post from 1-2 years to 20 years. You can also apply additional treatments at the base of the post where it touches the ground, ensuring an even longer life.

Enhancing Post Durability: Alternatives to Direct Burial

Treated in-ground posts are fine for most applications, but here are 2 more innovative options for even greater durability:

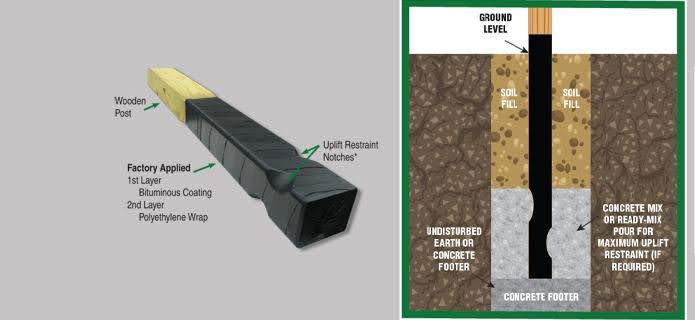

GreenPost

GreenPost is a cutting-edge solution designed to protect wooden posts from decay and rot. Here’s how it works:

· Plastic Wrap: The core of GreenPost’s technology is a heavy-duty polyethylene wrap that is coated on the inside with bitumen. When heat is applied, the bitumen liquifies and penetrates the wood, creating a secondary moisture-resistant layer. Not only does it keep the bad stuff out, but it also keeps the good stuff in.

· Uplift Restraint Notch: This feature provides enhanced resistance to wind uplift, ensuring that the posts remain securely in place even under harsh conditions. Maximum anchorage is achieved when combined with concrete footers.

· Termite Tested and Building Code Compliant

Perma-Column®

Perma-Column® elevates wooden posts out of the ground and eliminates rot. The in-ground post is actually a specially-built concrete post. Engineers design this foundation to be 3x stronger than standard concrete. This system combines the economy of post-frame construction with the durability of a concrete foundation.

- Eliminates direct soil contact

- Easy to install

- Stronger foundation

- Lifetime Warranty

To learn more about the innovative concrete post system, visit the Perma-Column® official website.

Conclusion: Making the Right Choice for Burying Wooden Posts

In conclusion, while burying pressure-treated wooden posts in the ground is generally fine for most applications, it’s important to know your options to make an informed decision. Solutions like GreenPost and Perma-Column® offer valuable alternatives that can enhance the quality and endurance of your pole building.

Timberline Buildings has been constructing high quality pole barns in Pennsylvania since 2003. With attention to detail and a focus on excellent service, pole buildings from Timberline Buildings are built to exceed your expectations. Ready to get started on your new pole barn? Contact us today for your free 1-day quote.