Pole Barn for Farm Equipment Storage

Practical Protection for Pennsylvania Farms

On a working farm, equipment is more than machinery—it’s time, money, and momentum. Tractors, skid steers, balers, implements, and attachments represent a major investment, and how you store them has a direct impact on their lifespan and reliability. For many Pennsylvania farmers, a pole barn for farm equipment storage offers a smart, flexible, and cost-effective solution.

Post-frame (pole) buildings have become the go-to structure for agricultural storage because they’re designed around function first. Instead of forcing your equipment to fit a building, the building is designed to fit your operation.

Why Proper Farm Equipment Storage Matters in Pennsylvania

Leaving equipment exposed to the elements takes a toll faster than most people realize. Pennsylvania’s climate brings moisture, freeze-thaw cycles, snow load, UV exposure, and mud—all of which shorten equipment life and increase maintenance costs.

A properly planned farm equipment storage building helps you:

- Reduce rust, corrosion, and weather damage

- Keep hydraulics, wiring, and tires in better condition

- Improve organization and workflow during busy seasons

- Protect your investment year-round

A pole barn doesn’t just store equipment—it supports how your farm operates day to day.

Why Pole Barns Are Ideal for Farm Equipment Storage

Pole barns are uniquely suited for agricultural equipment storage because of their structural flexibility.

Clear-span interiors mean no interior load-bearing walls getting in the way of parking or maneuvering large machinery.

Custom dimensions allow you to design around your largest piece of equipment—not the other way around.

Tall eave heights make it easy to store tractors with cabs, loaders, or raised attachments.

For farmers who plan to expand their fleet over time, this adaptability matters. A pole barn built today can still work for you ten or twenty years from now.

See how different sizes, door placements, and layouts work before anything is built. Try our Design Tool to explore popular farm equipment storage layouts and customize them to fit your operation.

Key Design Considerations for Farm Equipment Storage Buildings

No two farms are identical, and equipment storage buildings shouldn’t be either. These are the decisions that make the biggest difference.

1. Building Size and Layout

Start with the equipment you own now—but don’t stop there. Think about:

- Turning radius inside the building

- Space to open cab doors and service equipment

- Future equipment upgrades

Many farmers find it helpful to sketch layouts or experiment with door placement and dimensions before finalizing a plan. Visualizing the space early can prevent costly adjustments later.

If you want to explore layouts and dimensions, designing a building digitally can help you see what works before anything is built.

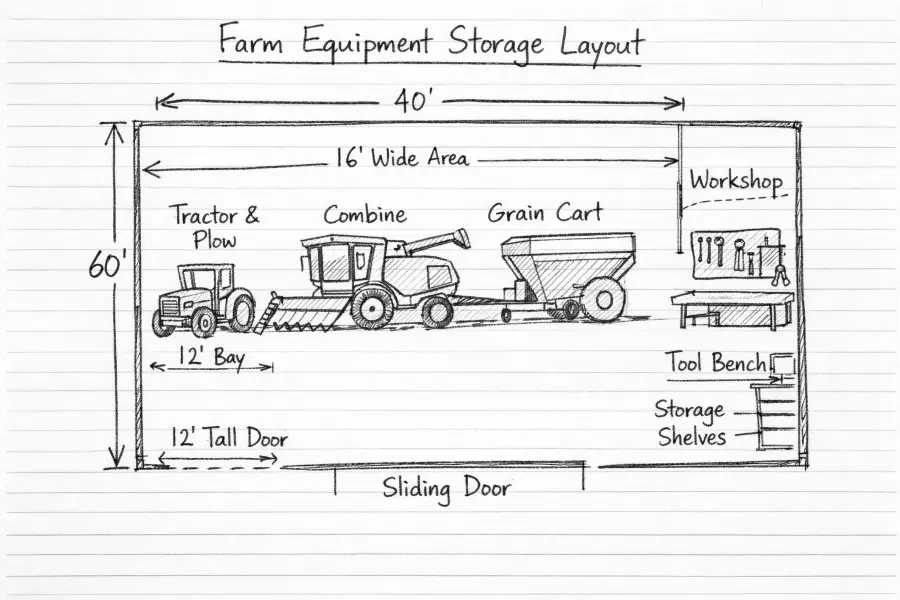

Sketching equipment placement helps farmers plan building size and turning space effectively.

If you’ve sketched your layout and know your dimensions, submit your details and request a quote. Our team will review your specifications and prepare a customized estimate based on your equipment and site.

2. Door Widths and Heights

Doors are often the most overlooked—and most important—part of an equipment storage building.

Consider:

- Overhead vs. sliding doors

- Widths that accommodate headers, loaders, or dual wheels

- Heights that allow equipment to enter without lowering attachments

Planning door sizes around your largest equipment avoids daily frustration and long-term limitations.

Oversized doors prevent clearance issues for modern agricultural machinery.

3. Eave Height and Roof Design

Low ceilings can quickly become a problem when storing modern agricultural equipment. Adequate eave height:

- Improves airflow

- Allows safer movement of tall machinery

- Provides flexibility for future use

Roof pitch also plays a role in snow shedding and interior clearance—especially important in Pennsylvania winters.

Adequate eave height provides safe clearance for tractors with cabs and raised implements.

4. Open vs. Fully Enclosed Storage

Some farms prefer open-sided structures for quick access and airflow. Others need fully enclosed buildings for weather protection or security.

Many equipment storage pole barns fall somewhere in between, with:

- One or two open sides

- Partial enclosures

- Strategic wind protection

The right balance depends on how often equipment is used and the conditions it’s exposed to.

Open-sided structures offer airflow and quick access for frequently used equipment.

Proper site preparation is just as important as the structure itself. Before finalizing your layout, review the key steps for grading, drainage, and foundation planning.

Flooring and Site Considerations

Pole barns offer flexibility when it comes to flooring. Options range from compacted stone to concrete slabs, depending on use and budget.

Things to think about:

- Drainage and site slope

- Weight of equipment

- Maintenance and cleaning needs

Good site preparation ensures the building performs well long after construction is complete.

Proper flooring and site preparation improve durability and long-term performance.

Ventilation and Long-Term Equipment Health

Even when equipment is stored indoors, moisture can still be an issue. Proper ventilation helps:

- Reduce condensation

- Prevent mold and corrosion

- Improve overall air quality inside the building

Simple design choices—like ridge vents, overhangs, or strategic openings—can make a noticeable difference over time.

Designing a Multi-Purpose Farm Equipment Storage Pole Barn

One of the biggest advantages of a pole barn is versatility. An equipment storage building today can evolve into:

- A workshop

- Seasonal storage for hay or materials

- A combination storage and maintenance space

Designing with flexibility in mind allows the building to grow with your operation instead of limiting it.

Equipment storage buildings can evolve into workshop and maintenance spaces.

For owners exploring financing options as part of that planning, our overview of

👉 How to Finance a Pole Barn

covers common approaches and considerations.

A Practical Investment for Pennsylvania Farms

For farms across Pennsylvania, pole barns strike a balance between durability, customization, and value. They’re designed for real work, real weather, and real equipment—not showroom conditions.

Whether you’re storing a single tractor or an entire fleet, a thoughtfully designed equipment storage building protects your investment and supports how you work every day.

Many farmers start the planning process by outlining their equipment and experimenting with building layouts to see what fits best. Others prefer to share their needs and have a custom plan prepared for them. Both approaches help clarify next steps without pressure.

Building a Smarter Farm Equipment Storage Pole Barn

A pole barn for farm equipment storage isn’t about building bigger—it’s about building smarter. When the structure is designed around your equipment, workflow improves, maintenance decreases, and your operation runs more efficiently.

Taking time to plan size, layout, access, and future needs ensures your building works for you—not against you—for years to come.

A pole barn for farm equipment storage isn’t about building bigger—it’s about building smarter. When the structure is designed around your equipment, workflow improves, maintenance decreases, and your operation runs more efficiently.

Taking time to plan size, layout, access, and future needs ensures your building works for you—not against you—for years to come.

Ready to Take the Next Step?

Whether you’re still exploring layouts or ready to move forward, you have options:

- Use a design tool to explore layouts and features

- Submit your dimensions and request a detailed quote

- Explore our popular equipment storage configurations

Each step helps refine expectations before making larger decisions.

No signup • Takes 2 minutes

Personalized pricing • No obligation

Built in Pennsylvania • Amish Craftsmanship • Trusted Since 2003