Pole Building vs Traditional Construction in Pennsylvania

Cost, Speed, Durability, and Long-Term Value Compared

Pole building vs traditional construction is one of the most common decisions property owners face when planning a new building in Pennsylvania. The construction method you choose will directly affect cost, timeline, and long-term performance. Below is a clearer, more scannable breakdown—each section starts with a short takeaway, followed by the facts.

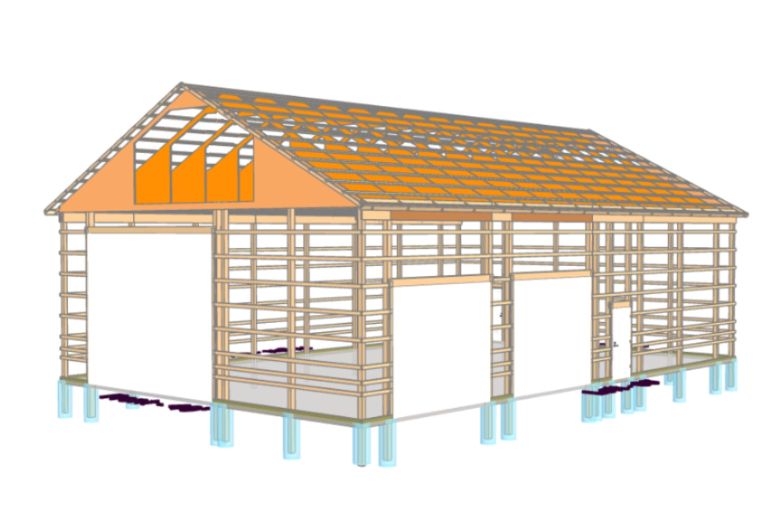

Side-by-side comparison of post-frame pole building construction and traditional stick-built construction commonly used in Pennsylvania.

Understanding the Two Building Methods

When comparing pole building vs traditional construction, cost differences are driven by materials, labor, and foundation requirements—not by quality.

Pole Building Cost Profile

Post-frame construction is typically 15–30% less expensive per square foot in Pennsylvania.

- Reduced concrete usage

- Fewer framing members

- Faster labor cycles

- Less excavation and site disruption

Traditional Construction Cost Profile

Stick-built structures generally cost more due to system complexity.

- Full frost-depth foundations

- Higher concrete costs

- Longer labor timelines

- Greater material waste

Post-frame pole building SmartBuild design illustrating structural layout and load distribution.

Trying to compare real numbers for your project?

See how a post-frame layout would look and function on your property before making a decision.

👉 Explore Pole Building Designs

.

1. Cost Comparison in Pennsylvania

Pole Building Cost Profile

Post-frame construction is typically 15–30% less expensive per square foot in Pennsylvania.

- Reduced concrete usage

- Fewer framing members

- Faster labor cycles

- Less excavation and site disruption

Traditional Construction Cost Profile

Stick-built structures generally cost more due to system complexity.

- Full frost-depth foundations

- Higher concrete costs

- Longer labor timelines

- Greater material waste

Key takeaway: Pole buildings deliver a stronger cost-to-value ratio for most non-residential uses.

Post-frame pole building interior with wide-span trusses, allowing maximum usable space with fewer structural materials.

2. Speed of Construction (Critical in PA Weather)

Pennsylvania weather shortens the build window—speed matters more than most people expect.

Pole Buildings

Post-frame construction minimizes weather-sensitive phases.

- Faster dry-in

- Fewer concrete delays

- Shorter overall schedules

Traditional Construction

Stick-built projects face more weather risk.

- Foundation curing delays

- Multiple inspection stages

- Longer exposure to rain and freezing temperatures

Key takeaway: Pole buildings reduce schedule risk in unpredictable PA seasons.

Need your building completed on a predictable schedule?

Start with a layout that minimizes delays and weather risk.

👉 Design Your Building Layout

.

Post-frame pole building dried-in quickly during winter conditions, reducing weather delays common in Pennsylvania construction.

3. Structural Performance & Snow Load

Both methods can meet code—but how they handle stress is different.

Post-Frame Structural Advantages

Modern pole buildings are engineered, not improvised.

- Designed for county-specific snow loads

- Wide-span trusses reduce interior load points

- Structural flexibility helps dissipate stress

Traditional Structural Characteristics

Traditional framing is strong but often inefficient.

- Dense framing increases material use

- Load paths are less optimized

- Strength gains don’t always justify added cost

Key takeaway: Engineering quality matters more than framing density.

Engineered wide-span trusses in a post-frame pole building distribute snow loads efficiently while reducing interior load points.

Every county in Pennsylvania has different snow load requirements.

Share your location and building size — we’ll confirm what your structure needs.

👉 Request A Quote

.

4. Energy Efficiency & Insulation

Energy performance depends on design—not construction labels.

Pole Building Insulation Systems

Today’s post-frame buildings can be highly efficient.

- Insulated slabs and wall systems

- Girt layouts designed for insulation depth

- Proper condensation control strategies

Traditional Construction

Still predictable, still effective—but no longer exclusive.

- Familiar insulation methods

- Higher baseline cost for similar R-values

Key takeaway: Properly designed pole buildings can match or exceed traditional energy performance.

Post-frame pole building insulation system designed for proper thermal performance, air sealing, and condensation control.

5. Design Flexibility & Future Expansion

How a building adapts over time often matters more than how it starts.

Pole Buildings

Post-frame structures are easier to modify.

- Clear-span interiors

- Easier future expansions

- Flexible use (garage → shop → storage)

Traditional Construction

Stick-built structures are more rigid.

- Load-bearing walls limit changes

- Expansions require foundation work

- Higher modification costs

Key takeaway: Pole buildings are better suited for evolving needs.

A newly integrated post-frame addition shows how pole buildings can be added to existing structures and expanded over time.

Planning for future expansion or multi-use space?

Start with a flexible layout and adjust as your needs grow.

👉 Customize a Pole Building

.

Which Option Makes Sense for You?

The right choice depends on use—not assumptions.

Pole Building Is a Strong Fit If:

- Budget efficiency matters

- Speed is important

- Interior flexibility is a priority

- The building is a garage, shop, agricultural, or light commercial structure

Traditional Construction Makes Sense If:

- You’re building a full residential home

- Zoning or code mandates it

- Architectural requirements demand conventional framing

A completed building solution illustrating how the right construction method depends on use, site conditions, and long-term needs.

The Pennsylvania Reality

Most property owners don’t need “more building”—they need smarter building.

At Timberline Buildings, we see this repeatedly:

Post-frame construction succeeds in Pennsylvania because it aligns with soil conditions, climate demands, and cost pressures—not because it’s a shortcut.

A post-frame building designed to fit Pennsylvania soil, climate, and real-world use—focused on practical performance, not overbuilding.

What’s Next in This Series

This article is the starting point of our weekly Pennsylvania building guide.

Up next:

24×32 Pole Barn Cost in Pennsylvania: Real Pricing, DIY Kits vs Turnkey Builds

Instead of comparing every size, we’ll go deep on one of the most requested and practical building sizes in PA—the 24×32 pole building—covering:

- Real-world pricing ranges

- What drives cost up or down

- DIY kit vs turnkey construction trade-offs

Where to Go From Here

If ideas have started to take shape, there’s no need to rush the process.

Choose the next step that fits where you are right now.

Explore & Visualize Your Ideas

If you’re still thinking through layout, size, or options, start by seeing what’s possible.

✅Customize This Building

Use a real project as a starting point and adjust it to fit your needs.

Share Your Ideas — No Pressure

If you have a general direction but want feedback, sharing your ideas is an easy way to move forward.

✅Share Project Details

Tell us how you’re thinking about using your building, and we’ll help shape the plan.

Ready for Pricing?

If you’re ready to talk numbers and timing, you can request a detailed quote at any time.

✅Request a Quote

Get clear pricing based on your project goals.